Introduction

When developing plastic parts for automotive, electronics, or athletic applications, the prototyping phase can make or break your project timeline and budget. At Haumann Technology, we’ve refined our CNC prototyping processes over 10 years to deliver precision results that accelerate your path to market.

What Makes CNC Prototyping Essential?

CNC prototyping bridges the critical gap between concept and mass production. Unlike traditional prototyping methods, CNC machining delivers:

• Dimensional accuracy within ±0.01mm tolerances • Material flexibility – test with your actual production plastics • Rapid turnaround – prototypes ready in 5-15 days • Cost-effective validation before committing to injection mold tooling

Our 30-Day Concept-to-Prototype Process

Week 1: Design Analysis & Optimization

Our German-trained engineers review your CAD files, identifying potential manufacturing challenges and suggesting design improvements that enhance both functionality and manufacturability.

Week 2-3: Precision Machining

Using our state-of-the-art CNC equipment, we machine your prototypes from production-grade materials including PA6GF reinforced plastics, ensuring your tests reflect real-world performance.

Week 4: Quality Validation & Delivery

Every prototype undergoes our ISO 9001-certified quality checks, including dimensional verification and material property testing.

Key Considerations for Successful CNC Prototyping

Material Selection: Choose materials that match your production requirements. Our team can recommend alternatives that offer similar properties at reduced prototype costs.

Tolerance Requirements: Define critical dimensions early. Our CNC capabilities handle tight tolerances, but understanding your true requirements optimizes both cost and timeline.

Quantity Planning: Consider ordering 3-5 prototypes for comprehensive testing, including destructive testing scenarios.

When CNC Prototyping Makes Financial Sense

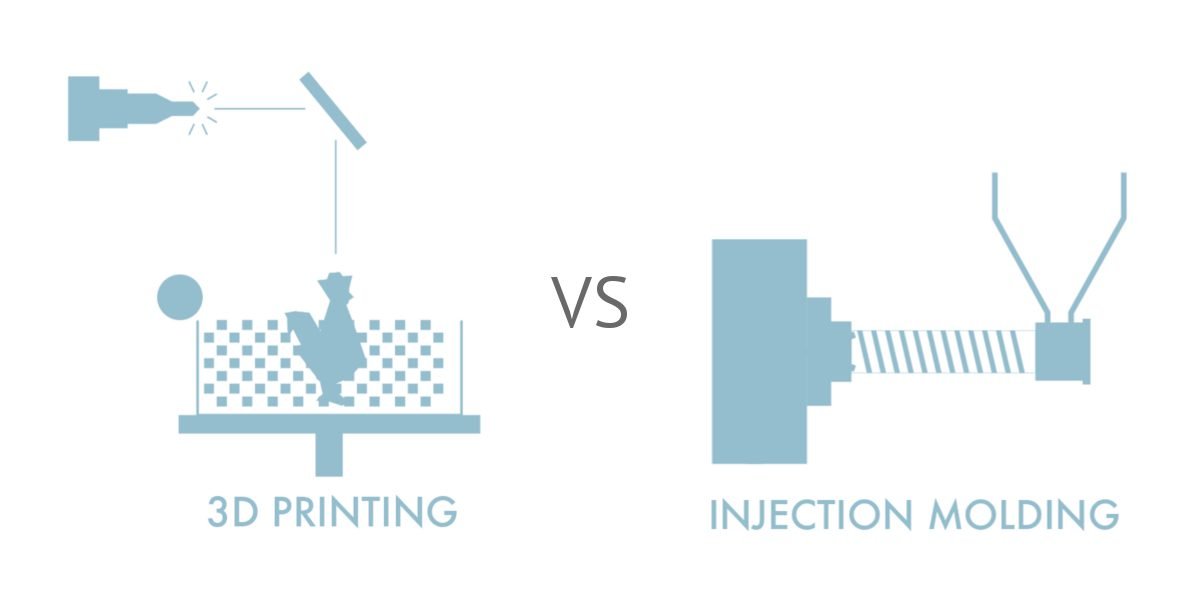

For projects requiring fewer than 100 test units, CNC prototyping typically offers 60-80% cost savings compared to prototype injection molding. This approach particularly benefits:

• Complex geometries with undercuts • Multi-material assemblies • Parts requiring post-machining operations • Projects with evolving design requirements

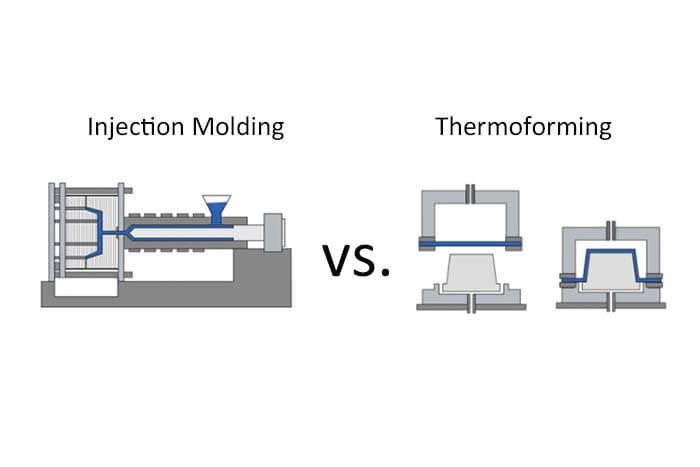

Transitioning from Prototype to Production

Our integrated approach means your CNC prototype data directly informs your injection mold design. This continuity reduces production risks and ensures your final parts match prototype performance.

Conclusion

Ready to accelerate your product development? Contact Haumann Technology for expert CNC prototyping that delivers precision results on time, every time. Our German engineering standards and 30-day turnaround process ensure your project stays on track from concept to mass production.