- globalsales@haumann-group.com

- +1 (832) 497-0809

From DFM and tooling to high-volume injection molding and assembly, Haumann Group helps OEMs reduce production risk, improve quality, and scale plastic parts manufacturing—led by our Houston-based engineering team.

Houston-based communication & project management.

German-engineered tooling for tight tolerances and repeatability.

Scalable production from samples to mass production.

USA First Production with Global Scalability: Houston supports responsive engineering, CNC, and local project leadership while Foshan enables cost-efficient capacity for high-volume injection molding and mass production plastic parts when needed.

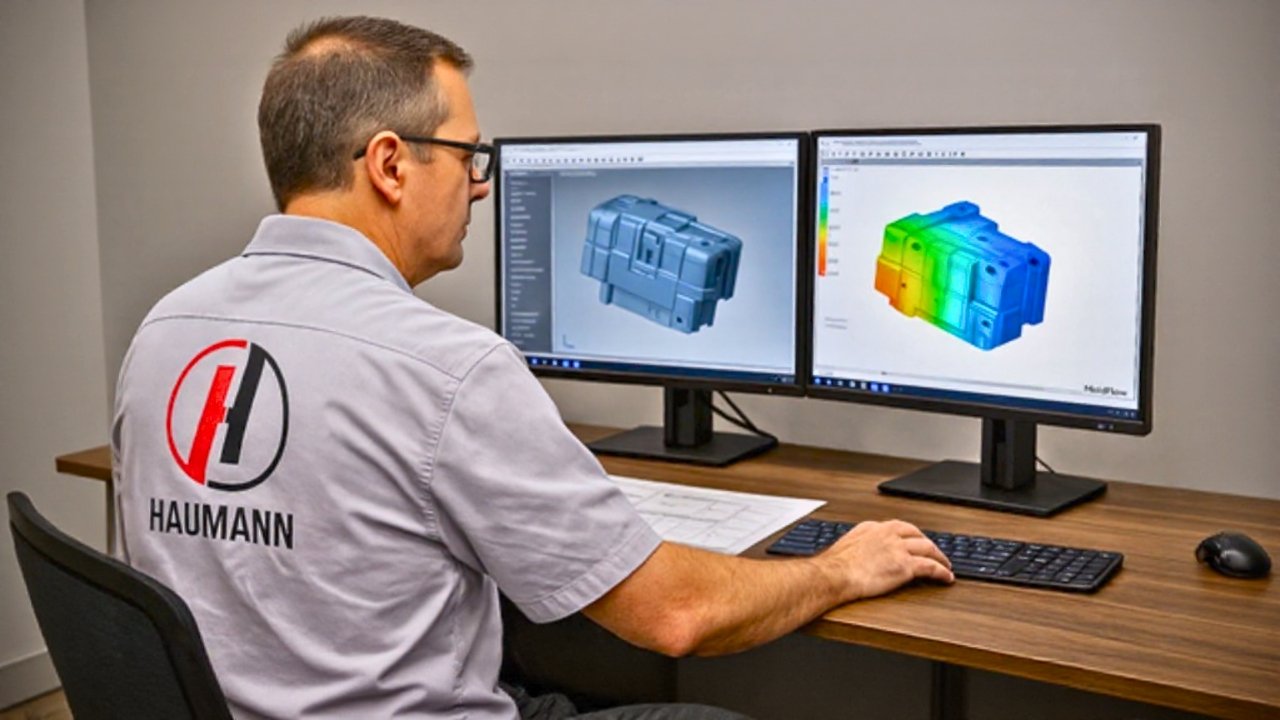

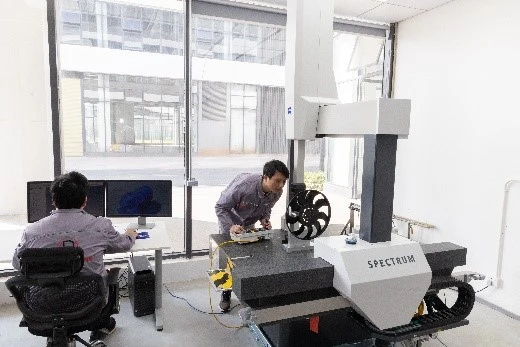

German-Engineered Tooling + Unified QC: We build repeatable tooling and validate output with CMM, 3D scanning, and first-article inspection so your injection molded components meet spec from pilot runs to full production.

One Partner for OEM Plastic Parts Manufacturing: End-to-end workflow: DFM → Design → CNC → Tooling → Molding → Volume Production → Assembly. Reduce supplier handoffs, shorten ramp-up time, and protect part quality at scale.

Work with a Houston-based team for fast communication, engineering alignment, and predictable execution. When programs scale, our global capacity supports efficient plastic parts manufacturing with one quality standard and one accountable partner.

U.S.-based project ownership from start to production

Scalable output for high-volume injection molding program

Our team designs tooling and molding processes to reduce risk early improving accuracy, stability, and cycle performance for custom injection molding services and high-volume production.

From micro features to larger housings, we deliver consistent results across complex geometries, tight tolerances, and engineering-grade materials.

Get quick responses, clear updates, and engineering-to-engineering communication especially valuable for U.S. OEM teams managing timelines and quality.

We manage the full path from design review through tooling, molding, and assembly reducing supplier complexity and improving on-time production.

High-volume quick-turn molding delivered from U.S. and China sites.

Expert molding with engineering-grade high-temperature materials.

Scientific molding and automation ensure consistent production quality.

Scalable production from

samples to millions of parts.

German-engineered tool and mold design for tight tolerances.

Multi-cavity, insert, and overmold tooling for complex plastic parts.

Complete mold repair, refurbishment, and preventive maintenance services.

Fast tooling programs with local and global manufacturing support.

Design for manufacturability reviews to reduce cost and production risk.

Detailed tolerance and stack-up analysis for critical plastic components.

Material and resin selection support based on performance requirements.

Gate, flow, and cooling analysis to optimize cycle time and quality.

Functional prototype parts for early design and fit evaluation.

Pre-production sample runs for mold and manufacturing verification.

Rapid iteration cycles to refine part design before full tooling.

Consistent sample testing to confirm production-ready performance.

See how our custom injection molding services transition from precision tooling to high-volume production. With Houston-based engineering and scalable manufacturing infrastructure, we deliver consistent, production-ready plastic parts for global OEM programs.

|Marine

|Footwear

|Housings

Lightweight carbon composite parts that complement our injection molding programs ideal for sports products and performance components where stiffness-to-weight matters.

Turnkey assembly for ready-to-ship products, including functional checks, quality validation, and packaging so you can reduce vendors and accelerate launches.

Measurement and inspection built into our process to protect dimensional accuracy and batch-to-batch consistency.

Verify full geometry on complex surfaces and tight tolerance features to confirm parts match CAD.

Confirm critical dimensions before production begins aligning tooling output to your engineering requirements.

Repeatable probing and reporting for high-precision programs ideal for automotive and performance components.

Insights on injection molding, tooling, and OEM manufacturing plus project updates from Houston.

Precision tooling, reliable production, and end-to-end manufacturing support backed by certified systems and proven engineering.

If you’re ramping to volume, we help stabilize tooling, reduce scrap, and protect critical dimensions so your team can hit production targets with confidence.

Multi-cavity tooling and repeatable cycle control

Tight tolerance validation with inspection reporting

Secondary operations and assembly available

Houston-led project management

Share your part design for an engineering feasibility review focused on manufacturability, risk reduction, and cost-saving opportunities.

We manufacture injection molded components for OEMs in high-demand markets—especially where quality and repeatability matter.

Priority order for tiles:

Sports & Outdoor Products ( “performance components” / wakeboarding)

Home Appliances & Lifestyle

Automotive Components

Then the rest.

Experience supporting global OEM programs brands shown where permitted.