Introduction

I know how challenging it can feel to bring a product idea to life. Every manufacturer faces tight deadlines, rising costs, and the pressure to maintain high-quality standards. That’s why I want to talk about custom injection molding solutions today. These solutions have transformed the way businesses develop, produce, and assemble products efficiently.

When I first worked with clients looking to scale their production, I noticed one thing. Many struggled with prototypes that didn’t match final production quality. Others wasted time and money on mass production that failed to meet precision requirements. Custom injection molding solutions solve these problems. They help you move smoothly from concept to finished product while keeping costs under control.

I’ve seen companies reduce their product development cycles by up to 40% using tailored injection molding strategies. That’s not just a statistic—it’s a game-changer for any business competing in today’s fast-paced market.

In this blog, I’ll guide you through everything you need to know about custom injection molding solutions. From understanding what they are, to exploring benefits, and even steps to launch your own project—I’ll cover it all. Along the way, I’ll share insights, tips, and actionable strategies you can use immediately to gain a competitive edge.

By the end, you’ll see why investing in custom injection molding solutions isn’t just smart—it’s essential for any forward-thinking manufacturer.

What Are Custom Injection Molding Solutions?

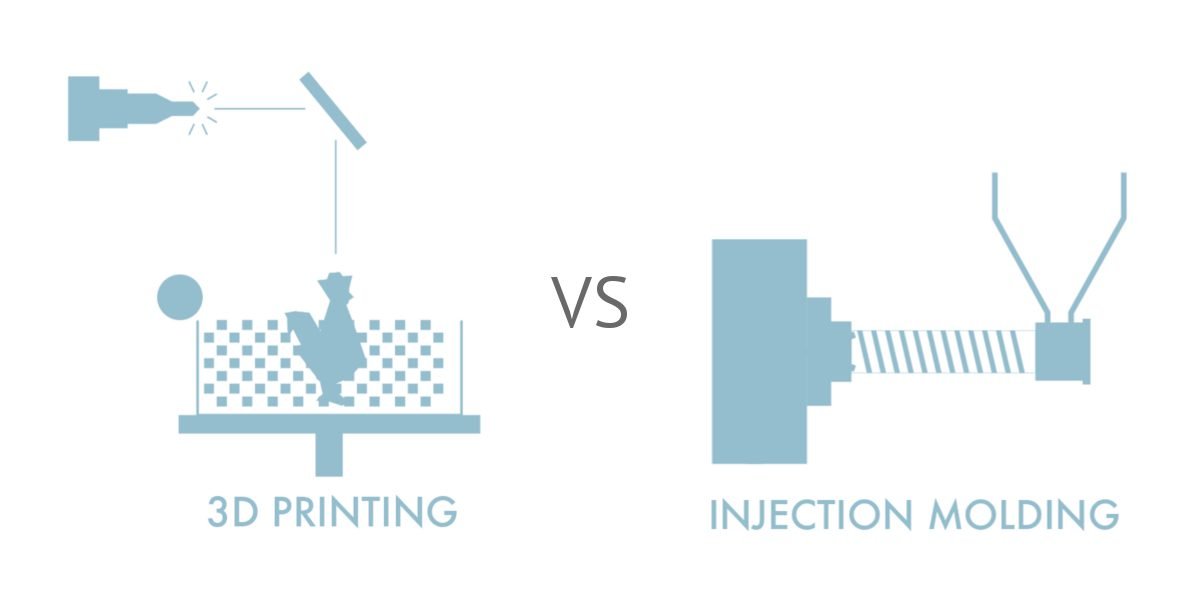

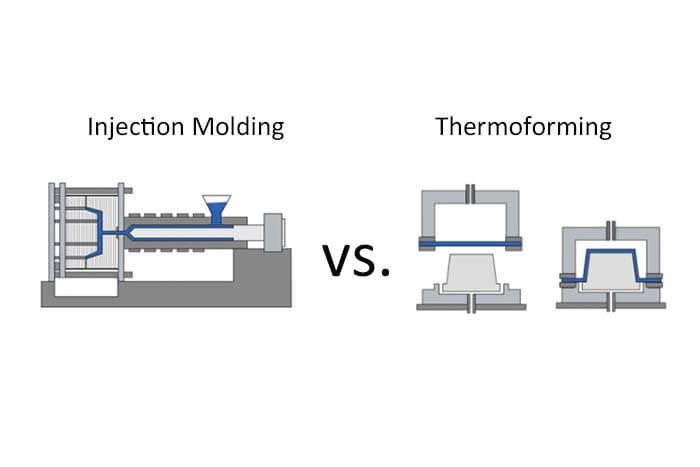

When I first learned about custom injection molding solutions, I realized they are more than just a manufacturing process. Simply put, they allow you to create plastic or composite parts tailored exactly to your design and functional needs. Unlike standard molding, custom solutions give you full control over material selection, precision, and production scale.

I’ve seen businesses struggle when they use off-the-shelf molds. They often face quality inconsistencies or costly redesigns. That’s where custom injection molding comes in. It eliminates guesswork. You get molds and processes designed specifically for your product. From prototypes to mass production, everything stays aligned with your goals.

These solutions aren’t just for large corporations. Even startups benefit. I’ve worked with small companies that needed low-volume, high-quality parts. Using custom molds, they tested designs rapidly, avoided waste, and entered the market faster. Rapid prototyping and precise material choices make this possible.

The technology behind it is fascinating. Custom injection molding uses high-precision machines, advanced cooling systems, and sometimes carbon composites or reinforced plastics.These innovations allow manufacturers to create durable, lightweight, and complex parts that standard molding cannot achieve.

If you’re asking me, the biggest advantage is flexibility. You control every detail—from part geometry to material strength. This level of customization reduces errors, improves product performance, and accelerates time-to-market. Minor details like wall thickness, surface finish, or mechanical tolerances can all be optimized.

In short, custom injection molding solutions give you the power to turn ideas into high-quality products efficiently. No compromises, no wasted effort—just precise, tailored results that meet your exact needs.

Faster Prototyping and Product Development

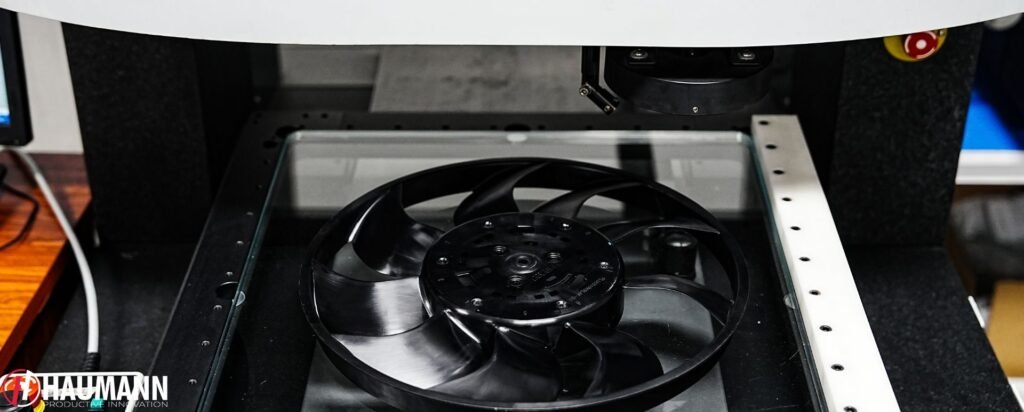

We understand how critical it is to move from an idea to a tangible product quickly. Custom injection molding solutions allow businesses to prototype efficiently and refine designs rapidly. This process helps companies test functionality, fit, and aesthetics before committing to full-scale production.

Through our experience, we have seen companies reduce prototyping time by up to 40% with tailored injection molding strategies.This happens because we design molds specifically for the product, avoiding repeated adjustments common with generic solutions. Every prototype is precise and ready for immediate testing.

Custom solutions also provide flexibility in materials and design. Businesses can experiment with high-performance plastics or carbon composites to achieve the exact strength, weight, and durability required. We optimize injection pressures, cycle times, and cooling systems to produce high-quality prototypes faster.

By using these solutions, businesses can identify design flaws early and make improvements without wasting time or resources. This approach reduces development costs, shortens time-to-market, and ensures the final product meets quality expectations.

In short, custom injection molding solutions accelerate the journey from concept to product. Companies gain a competitive advantage by delivering innovative, high-quality products faster. Rapid prototyping ensures that every product is tested, refined, and ready for seamless transition into scalable production.

Scalable Mass Production

When we first help clients transition from prototypes to full-scale production, we notice how many manufacturers struggle with scalability. Small batches work fine for testing, but scaling to thousands or millions of parts brings new challenges. That’s where custom injection molding solutions shine. They let businesses produce large volumes efficiently without sacrificing quality.

We have seen companies reduce production time by up to 35% when they implement tailored injection molding strategies. This happens because the molds, machines, and processes are designed specifically for each part’s geometry and materials. There’s no wasted time adjusting generic molds or dealing with inconsistencies.

Custom injection molding also provides flexibility in material selection and process optimization. For example, businesses can choose high-strength plastics or carbon composites for parts that need durability. They can also adjust cycle times, cooling systems, and injection pressures to maximize efficiency. Every detail is optimized for each product and production volume.

From our experience, scalable mass production isn’t just about quantity. It’s about maintaining precision, consistency, and reliability as order sizes grow. Companies that rely on generic solutions often face defects, delays, or rework costs. Custom solutions prevent these issues.

The bottom line is simple: custom injection molding solutions help businesses scale confidently. They meet deadlines, control costs, and maintain product excellence—no matter how large production runs become. This gives companies a competitive advantage and ensures quality products reach the market consistently.

High-Precision Component Assembly

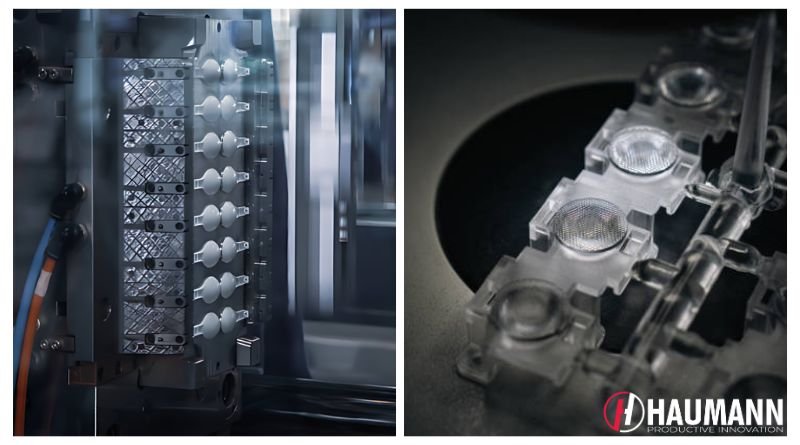

We know that producing high-quality parts is only one part of the equation. Custom injection molding solutions also include component assembly services, ensuring that every part fits perfectly and functions flawlessly. This integrated approach reduces errors and guarantees consistent product quality.

Through our experience, we have seen businesses improve assembly efficiency by up to 30% when using tailored injection molding and assembly strategies. By designing molds and assembly processes together, we eliminate misalignment issues and reduce rework. Every component arrives ready for seamless integration.

Custom assembly solutions also allow flexibility for complex or multi-part designs. Businesses can combine different materials, integrate mechanical or electronic parts, and maintain precise tolerances. We optimize the assembly workflow to ensure speed and accuracy, whether it’s a small batch or full-scale production.

We emphasize quality control at every stage. From injection molding to final assembly, every step undergoes strict checks. This approach minimizes defects, reduces delays, and strengthens customer confidence in the finished product.

In short, high-precision component assembly within custom injection molding solutions ensures that businesses deliver complete, reliable products. By combining molding and assembly, companies save time, reduce costs, and maintain a competitive advantage in the market.

Advanced Materials and Carbon Composites

We know that material choice can make or break a product’s performance. Custom injection molding solutions allow businesses to use advanced materials, including carbon composites, to create lightweight, durable, and high-strength parts. These materials deliver superior performance compared to traditional plastics, especially in demanding industries like Sport Footwears, automotive, electronics, and medical devices.

Through our work, we have seen companies improve part strength by up to 50% using carbon composite materials. These materials reduce weight without compromising structural integrity, making them ideal for applications that demand precision and durability.

Custom solutions give businesses flexibility in material selection and design optimization. Companies can combine carbon composites with high-performance plastics or other reinforced materials to meet specific mechanical, thermal, or chemical requirements.

We adjust injection pressures, cooling cycles, and mold designs to ensure every part meets exact standards.

Using advanced materials also reduces waste and improves efficiency. Parts are stronger, lighter, and often require fewer post-processing steps. Businesses gain a competitive edge by delivering products that are both high-quality and innovative.

In short, integrating advanced materials and carbon composites into custom injection molding solutions empowers businesses to produce durable, lightweight, and high-performance parts.

This combination of material innovation and precise molding ensures products meet demanding standards while maintaining cost efficiency and speed to market.

How Custom Injection Molding Solutions Give You a Competitive Edge

We understand that in today’s fast-paced market, standing out is more important than ever. Custom injection molding solutions provide businesses with a clear competitive edge by combining speed, precision, and flexibility in product development and manufacturing.

By using tailored molds and processes, companies can reduce time-to-market significantly. We have seen businesses launch products up to 40% faster compared to standard molding methods. Faster development cycles mean businesses can respond quickly to customer demands and industry trends.

Custom solutions also improve product quality and consistency. Every part is manufactured to precise specifications, reducing defects and minimizing costly rework. This consistency strengthens brand reputation and builds customer trust.

We also help businesses optimize costs without compromising quality. By selecting the right materials, fine-tuning injection parameters, and integrating assembly processes, companies lower waste, reduce production errors, and achieve better overall efficiency.

Additionally, using advanced materials like carbon composites allows businesses to create innovative, lightweight, and high-strength products. This innovation attracts high-value clients in industries such as automotive, aerospace, and medical devices.

In short, custom injection molding solutions empower businesses to innovate, scale, and deliver products efficiently. Companies gain faster production cycles, higher quality, cost savings, and the ability to meet evolving market demands. By leveraging these solutions, businesses not only stay competitive but also position themselves as leaders in their industries.

5 Steps to Launch Your Custom Injection Molding Project

We know that launching a successful custom injection molding project requires careful planning and execution. By following these five steps, businesses can bring their products to market efficiently and with confidence.

Step 1: Define Product Requirements

We start by helping businesses clearly outline product goals, including dimensions, functionality, and performance expectations. Precise requirements prevent costly redesigns later in the process.

Step 2: Select the Right Materials

Choosing the right material is critical. We guide companies in selecting plastics, carbon composites, or reinforced materials based on strength, weight, and durability needs.

Step 3: Prototype and Test

Rapid prototyping allows businesses to test designs and identify potential issues early. We create high-quality prototypes to validate functionality, fit, and aesthetics before moving to full-scale production.

Step 4: Scale Production

Once the prototype meets requirements, we optimize molds, cycle times, and injection parameters for efficient mass production. This ensures consistency, quality, and timely delivery.

Step 5: Integrate Assembly

For complex products, integrating component assembly into the molding process reduces errors and accelerates time-to-market. We provide precise assembly services to deliver ready-to-use products.

By following these steps, businesses can maximize efficiency, reduce costs, and maintain high product quality throughout the entire injection molding process. Custom injection molding solutions ensure every stage from concept to final product is optimized for success.

Conclusion

In today’s competitive market, businesses need every advantage to succeed. Custom injection molding solutions offer that advantage by combining precision, efficiency, and flexibility in product development and manufacturing.

We have seen companies reduce time-to-market, improve product quality, and lower production costs by implementing tailored molding strategies. [Insert external link for reference: source on efficiency improvements]. From prototyping to scalable production and high-precision assembly, these solutions empower businesses to deliver innovative products consistently.

Using advanced materials, including carbon composites, further enhances product strength, durability, and performance. By leveraging these materials and customized processes, companies gain a clear edge over competitors who rely on standard molding methods.

Ultimately, investing in custom injection molding solutions is more than a manufacturing decision—it’s a strategic choice. Businesses that adopt these solutions can innovate faster, scale efficiently, and consistently meet market demands with high-quality products.

We encourage you to explore how custom injection molding can transform your product development process and position your business as a leader in your industry. Partnering with a trusted OEM injection molding supplier ensures you achieve maximum efficiency, quality, and success.