Introduction

When it comes to sports, the gear you use can make all the difference. The right shoes, racket, or even protective gear can turn a good player into a great one. But here’s a question we don’t often think about: how is this gear actually made?

The truth is, sports equipment manufacturing is going through a huge transformation. What used to be all about traditional methods has now evolved into high-tech, sustainable, and highly innovative production. From smart fabrics that improve performance to eco-friendly sports gear made with recycled materials, the industry is pushing the limits of what’s possible.

At the center of this change are companies like Haumann Technology, part of the Haumann Group, which focus on advanced materials and innovative manufacturing solutions. By combining new technologies with a strong focus on sustainability, they’re not just producing better equipment — they’re also helping athletes perform at their best while supporting a cleaner, greener planet.

In this article, we’ll take you behind the scenes of the sports manufacturing world. You’ll discover the processes, the challenges, and the breakthroughs that are shaping the future of innovation in sports equipment. Along the way, we’ll also share how leaders like Haumann Technology are redefining athletic potential and setting new standards for the industry.

The Evolution of How Sports Equipment Manufacturing

Sports equipment hasn’t always been sleek or high-tech. In fact, sporting goods manufacturing started off in a very simple way. Back then, most gear was handmade using wood, leather, and natural fibers. Craftsmen would carefully shape wooden bats, stitch leather balls, or knit wool jerseys. These products worked, but they didn’t give athletes the speed, precision, or comfort they now expect. This early stage relied on manual labor and traditional skills, with little help from advanced innovation.If you’re curious about how equipment first developed, here’s a deeper look at the history of sports equipment.

From Handcrafted Beginnings to Industrialization

As more people embraced sports, the need for better, more reliable equipment grew quickly. The Industrial Revolution played a huge role in meeting that demand. With machines and mass production, manufacturers could make sporting goods faster, at lower costs, and with greater consistency. Traditional materials like wood and leather began to give way to rubber and synthetic fibers, which were stronger, more durable, and better suited for performance.This period set the groundwork for the sports industry we know today, where equipment isn’t just functional it’s accessible to more people than ever.

How Technology and New Materials Are Changing the Game

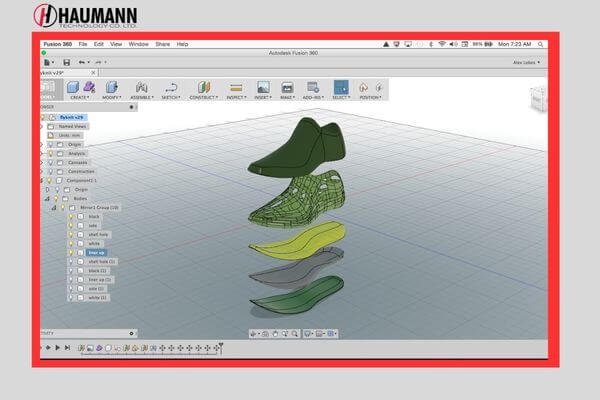

In recent decades, technology has completely transformed how sports gear is designed and produced. Tools like CAD (computer-aided design) and CAM (computer-aided manufacturing) allow every component to be precisely tested before it’s made. Robotics and automated production lines help maintain quality while speeding up manufacturing.At the same time, materials have evolved dramatically. Carbon fiber, smart textiles, and other advanced materials are making equipment lighter, stronger, and more responsive. These innovations give athletes an edge while also paving the way for smarter and more sustainable gear.At Haumann Technology, part of the Haumann Group, we apply these same principles. By blending innovative design with advanced materials, we help push the boundaries of sports equipment manufacturing supporting the industry as it moves toward smarter, high-performance, and environmentally conscious solutions.

Key Technologies Transforming the Industry

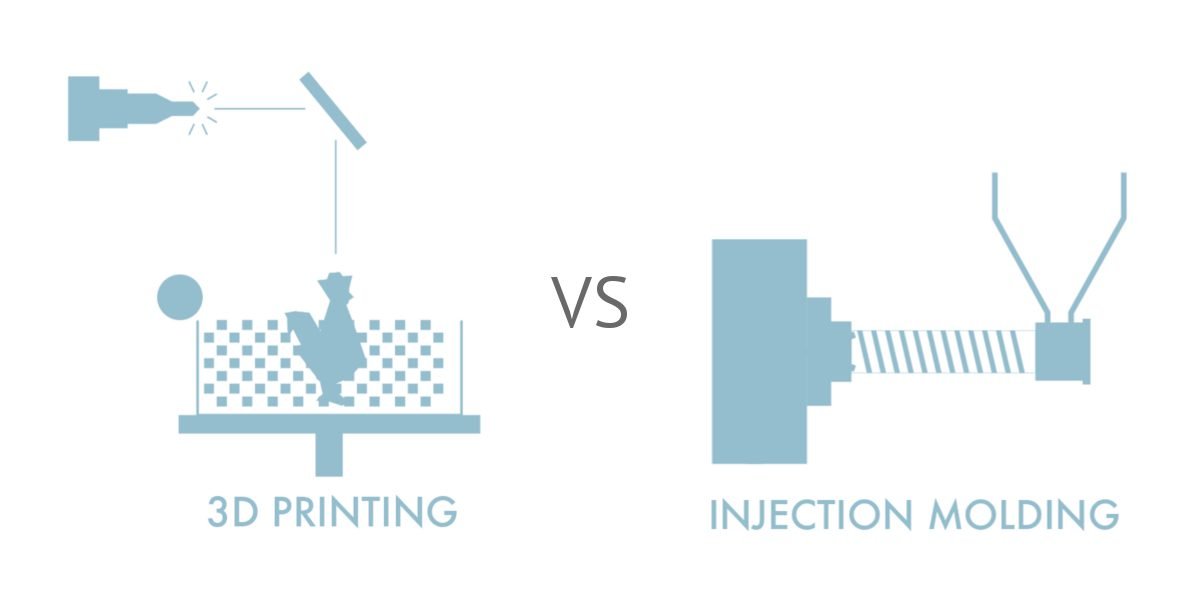

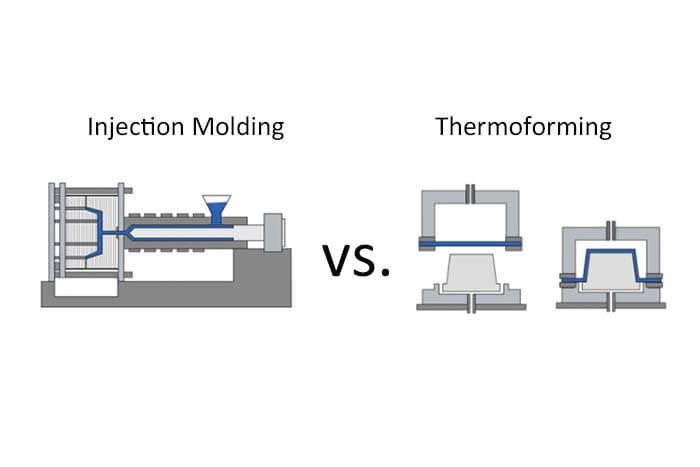

3D Printing and Customization

One of the biggest game-changers is 3D printing. Unlike traditional manufacturing, which can require complicated molds and multiple steps, 3D printing allows manufacturers to create complex designs in a single, smooth process. This means gear can be custom-made for individual athletes, perfectly fitting their needs and style. From shoes to protective gear, 3D printing is helping companies create highly specialized equipment that improves comfort and performance.

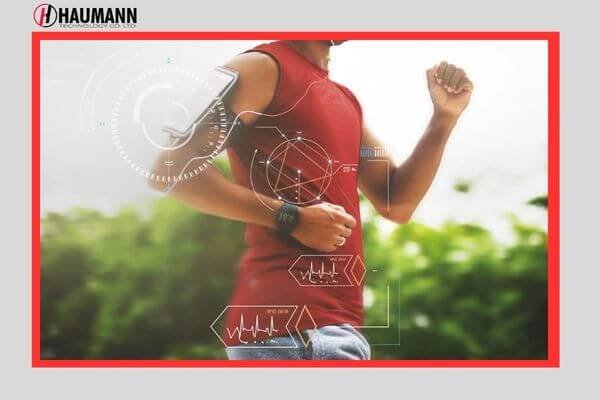

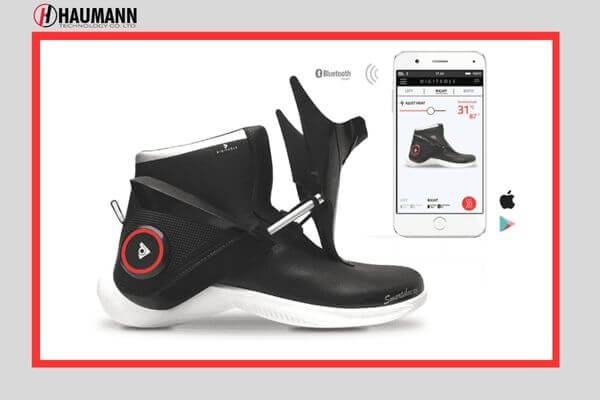

Smart Fabrics and Wearable Sensors

Another breakthrough is smart fabrics and wearable sensors. These advanced materials can track an athlete’s movements, heart rate, and other important stats in real time. This data helps athletes and coaches make better decisions about training and recovery. Smart fabrics also have practical benefits like keeping you cool, managing moisture, and boosting overall comfort during activity. Integrating these technologies into gear is helping athletes perform smarter and safer.

Artificial Intelligence and Machine Learning

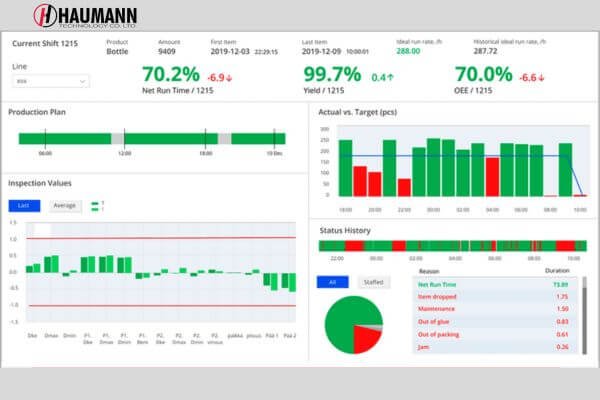

Today, technology is giving sports equipment a whole new edge. Artificial intelligence can study massive amounts of data to reveal insights designers might miss, like how materials react under stress or which shapes deliver better performance. Machine learning makes it possible to simulate product tests on computers, so prototypes don’t have to be physically built over and over, saving both time and money. Beyond design, AI-powered machines are improving the way gear is manufactured, making production faster, more accurate, and more consistent. As these technologies continue to evolve, they’re helping create sports equipment that is smarter, more efficient, and finely tuned for athletes’ needs.

Sustainable Practices in How Sports Equipment Manufacturing

Eco-Friendly Materials

One of the biggest changes is the shift to eco-friendly materials. Traditional plastics and synthetic fibers are being replaced with recycled or biodegradable alternatives. Some brands are making sneakers from recycled ocean plastics, while others are using plant-based materials to create sustainable apparel. These choices not only help the environment but also appeal to consumers who care about making greener choices.At Haumann Technology, part of the Haumann Group, we’re embracing similar approaches by integrating recycled and sustainable materials into our advanced manufacturing processes.

Energy Efficiency and Lean Manufacturing

Sustainability goes beyond materials. Many manufacturers are now using lean manufacturing techniques to cut waste and improve energy efficiency. This means optimizing workflows, reducing excess inventory, and using energy-efficient machines. Some companies even invest in renewable energy, like solar or wind power, to power their factories.These practices not only help the environment but also make production more cost-effective and efficient a win-win for both companies and consumers.

Circular Economy Principles

A forward-thinking strategy gaining traction in sports manufacturing is the circular economy. This approach focuses on designing products with their full life cycle in mind from the moment they’re made to the point they’re retired. Companies are now creating gear that’s easier to repair, recycle, or repurpose, cutting down on waste and giving products a longer lifespan. Some brands even run take-back programs, letting customers return old equipment for recycling or refurbishment.By embracing this circular mindset, the sports industry can shrink its environmental impact and turn sustainability into a lasting practice, rather than just a passing trend.

The Role of Innovation in Product Development

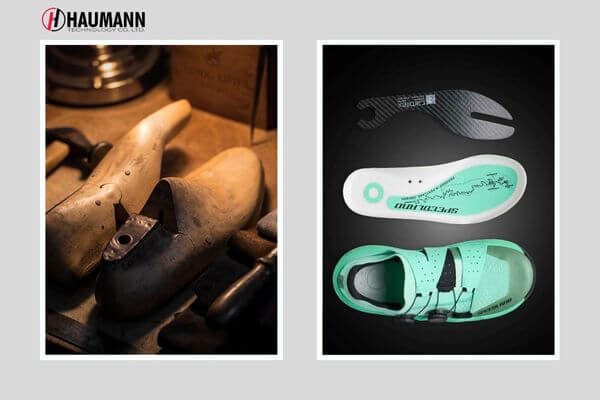

Breakthroughs in Material Science

Material innovation is one of the most exciting frontiers in sports equipment. Scientists and engineers are constantly developing new substances that are lighter, tougher, and longer-lasting. Take carbon fiber, for instance it has revolutionized everything from bicycles to tennis rackets thanks to its exceptional strength-to-weight ratio. Meanwhile, advanced foams are transforming footwear and protective gear, making them both more comfortable and safer for athletes.At Haumann Technology, we harness these advanced materials, including carbon fiber and custom composites, to craft sports equipment that keeps up with the performance demands of today’s athletes.

Biomechanics and Human-Centered Design

Another key area driving innovation in sports equipment is biomechanics the study of how the body moves and interacts with gear. By analyzing movement, designers can create products that better support athletes while minimizing the risk of injury. Take running shoes, for example: modern designs offer cushioning and support tailored to different foot shapes and running styles.Biomechanics also intersects with wearable technology. Motion-capture suits and smart sensors provide real-time feedback, helping athletes train more efficiently and perform at their best.

The Future of Aesthetic and Functional Design

It’s not just about function design matters too. Using tools like CAD and 3D modeling, designers can experiment with shapes and structures that weren’t possible before. This has led to gear that is both ergonomic and visually appealing.Manufacturers are also embracing user-centered design, meaning athletes are involved in the development process to make sure the products meet their real-world needs. This collaboration results in gear that feels natural, looks great, and works even better.

How Consumer Trends are Shaping Manufacturing Processes

Customization and Personalization

One of the biggest trends today is customization and personalization. Athletes don’t want generic gear anymore — they want equipment that reflects their style, fits perfectly, and enhances their performance. To meet this demand, manufacturers are using technologies like 3D printing and modular design. This makes it possible to personalize everything from color and design to size and technical features.At Haumann Technology, we embrace customized solutions that allow brands and athletes to create gear tailored to their exact needs, making sports equipment more personal and high-performing than ever.

The Health and Wellness Movement

Another major trend is the growing focus on health and wellness. People are paying more attention to physical and mental well-being, and they want equipment that supports a holistic approach to fitness. This includes ergonomically designed footwear, smart wearables, and recovery tools like foam rollers and massage devices.Manufacturers are responding by creating gear that not only improves performance but also prevents injuries and supports recovery, helping athletes train smarter and stay healthier.

Growing Demand for Sustainability

Sustainability is no longer optional it’s a key factor in consumer choices. More people are looking for eco-friendly sports products, from recycled materials to biodegradable components. Companies are now being pushed to reduce waste, lower carbon emissions, and adopt circular economy principles. At Haumann Technology, sustainability is part of our DNA. We focus on green manufacturing initiatives, such as using renewable energy, reducing waste, and integrating sustainable materials into our production processes. By aligning with what consumers care about, brands can build loyalty and attract more conscious customers.

The Impact of Globalization on How Sports Equipment Manufacturing

Global Supply Chains and Sourcing

One of the biggest impacts of globalization is the expansion of global supply chains. Manufacturers now source materials and components from around the world to get the best quality at competitive prices. For instance, high-performance textiles might come from one country, while electronic sensors or advanced components are sourced from another.At Haumann Technology, we work closely with international partners to access top-quality materials and cutting-edge technology, ensuring our products meet the highest standards.

Labor Costs and Ethical Responsibility

Globalization also means many companies move manufacturing to countries with lower labor costs, like Southeast Asia. This helps reduce prices while keeping products competitive. But it also brings up important questions about labor practices and ethics.Leading companies now focus on fair working conditions, ethical sourcing, and corporate social responsibility (CSR). At Haumann Group, we ensure all our partners follow strict ethical standards while delivering high-quality products.

Sharing Technology Across Borders

Globalization isn’t just about materials or costs it’s also about knowledge sharing. Advances in communication and transportation allow companies to collaborate on R&D, adopt new techniques, and quickly bring innovations to market. This interconnectedness has made the industry more competitive, encouraging constant innovation.For example, technologies like smart fabrics, 3D printing, and AI-driven design can now be shared and implemented across continents, helping companies like Haumann Technology create advanced, high-performance sports equipment for a global market.

Case Studies: Successful Brands Leading the Change

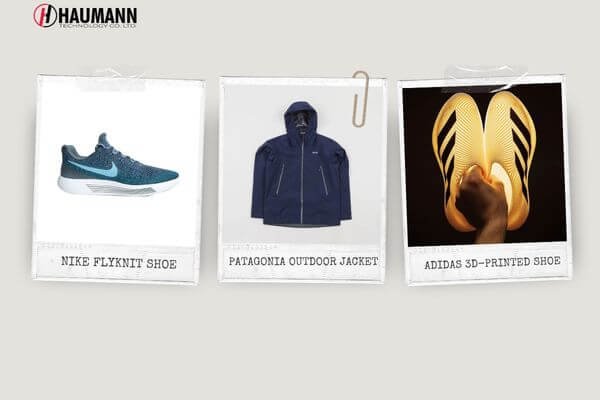

Nike: Flyknit Technology

Nike has long been a pioneer in both design and technology. Their Flyknit technology, introduced in 2012, is a perfect example. Using advanced knitting techniques, Flyknit creates a lightweight, form-fitting upper for shoes, which reduces waste while improving performance. Nike’s approach shows how a company can combine innovation with sustainability, setting a high standard for eco-friendly manufacturing in sports.

Patagonia: Worn Wear and Sustainability

Patagonia is known for its strong commitment to the environment. They use recycled materials, promote fair labor practices, and encourage customers to repair and reuse gear through their Worn Wear program. This approach not only reduces waste but also builds long-term loyalty among environmentally conscious consumers. Patagonia proves that sustainability and business success can go hand in hand.

Adidas: 3D Printing and Ocean Plastics

Adidas is also leading the way with innovation and sustainability. Their Futurecraft 4D shoes use 3D printing to create a high-performance midsole tailored for comfort and performance. On the sustainability side, Adidas partners with Parley for the Oceans to produce products made from recycled ocean plastics, reducing plastic waste while still delivering top-quality gear. At Haumann Technology, we take inspiration from these leaders by combining cutting-edge technologies, sustainable materials, and customized solutions to help brands produce advanced sporting goods efficiently and responsibly.

Challenges Facing the How Sports Equipment Manufacturing Industry

Rising Raw Material Costs

One of the main hurdles is the rising cost of raw materials. As more companies demand high-performance and eco-friendly materials, the price of sourcing these materials goes up. Manufacturers have to find the right balance between quality, sustainability, and keeping products affordable. At Haumann Technology, we tackle this challenge by investing in research and development to discover new materials and production methods that are both efficient and high-performing, helping brands deliver top-quality gear without breaking the bank.

Complex Global Supply Chains

Another challenge comes from global supply chains. Sourcing materials from different countries can be tricky — think logistics, trade regulations, or unexpected events like natural disasters or pandemics. These factors can delay production or increase costs. To stay ahead, manufacturers like Haumann Technology diversify suppliers and implement smart contingency plans, keeping production smooth and efficient even in unpredictable situations.

Transitioning to Sustainability

Finally, moving toward sustainable manufacturing can be challenging. While consumers want eco-friendly products, implementing green practices can be expensive and complicated. Companies need to adopt new technologies, change workflows, and comply with environmental regulations all while communicating their efforts clearly to build trust and loyalty. At Haumann Technology, sustainability is a core focus. We help brands transition smoothly by integrating green manufacturing practices, using renewable materials, and designing processes that are efficient and eco-conscious.

Future Trends in Sporting Goods Manufacturing

AI and Machine Learning in Manufacturing

Imagine a factory where machines can think ahead. That’s the power of artificial intelligence in sports equipment manufacturing. Instead of testing every prototype physically, AI can simulate how gear behaves under real conditions, spotting weak points before production begins. It also helps streamline the workflow, ensuring materials are used efficiently and processes run smoothly. At Haumann Technology, we’re exploring how AI can make production smarter and faster. By combining these insights with innovative engineering, we create equipment that performs better, lasts longer, and keeps athletes at the top of their game.

Smart and Connected Sports Equipment

Another big trend is smart and connected sports gear. From wearable tech to smart fabrics, athletes can now access real-time data to improve performance and prevent injuries. The Internet of Things (IoT) allows equipment to communicate with apps and other devices, creating a connected ecosystem. For example, smart shoes can provide personalized training tips, and connected gear can track performance over time. Haumann Technology is at the forefront of developing smart, data-driven sports equipment, helping athletes and brands embrace this personalized approach to training and fitness.

Sustainability as a Core Strategy

The future of sports equipment is closely tied to sustainability. Manufacturers are increasingly finding creative ways to make gear with less impact on the planet using recycled materials, conserving energy during production, and designing products that can be reused or repurposed. At the same time, being open and ethical about these practices helps companies earn the trust of environmentally conscious consumers. At Haumann Technology, sustainability is built into everything we do. From sourcing eco-friendly materials to developing greener production methods, we strive to make sports equipment that supports both athletes and the environment, proving that high performance and responsibility can go hand in hand.

Conclusion

The future of sports equipment is closely tied to sustainability. Manufacturers are increasingly finding creative ways to make gear with less impact on the planet using recycled materials, conserving energy during production, and designing products that can be reused or repurposed. At the same time, being open and ethical about these practices helps companies earn the trust of environmentally conscious consumers.

At Haumann Technology, sustainability is built into everything we do. From sourcing eco-friendly materials to developing greener production methods, we strive to make sports equipment that supports both athletes and the environment, proving that high performance and responsibility can go hand in hand.