In the sports and recreation field, Sports Equipment is the one that sets up performance, safety, and experience. The way an athlete executes and the time that the gear remains in service are all due to the quality of design and manufacturing, whether it is a pair of skis, a carbon-composite bicycle frame, or a simple racket for tennis.

We understand that producing sports equipment is not just a matter of manufacturing but also a matter of precision engineering, material science, and good manufacturing practices. Our company’s knowledge in different industries like automotive, aerospace, and consumer products has made us an obvious choice to provide trustworthy sports equipment product manufacturing to the brands looking for long-lasting and accurate sports products.

In this guide, we will uncover the underlying factors that lead to the production of high-quality sports gear, why they are important, and the different ways through which you can partner with the right manufacturer to convert your idea from paper to high-level reality.

Why Quality Sports Equipment Manufacturing Matters:

Sporting goods are literally put through their paces; they have to endure the rigors of sports performance, get huge impacts, suffer continuous movement, and be exposed to harsh environments. The manufacturing quality always provides regularity, safety, and performance.

- Durability: An Equipment that lasts longer under different conditions, like stress and wear.

- Precision: Every millimeter of design affects performance, from the flex of a golf club to the weight balance of a bicycle frame.

- Safety: When proper assembly and material integrity are in place, the risk of failure or injury is significantly reduced.

- Brand trust: Athletes and consumers link your brand with quality and dependability.

At this point, Haumann Group is already in the frontline where the combination of sophisticated engineering and molding skills, along with the modern technologies in production, brings in results on a large scale.

Step by Step: The Manufacture of Sports Equipment:

1. Design and Concept Development:

It all starts with an idea. Every single product that the company thinks of or works on has the main aspects of balance between the invention, the usefulness, and the needs of the market.

Our engineers not only enlighten the customers but also work hand in hand with them until the “final” product is made through the services of product development, prototyping, CAD modeling, and functional testing. During this stage, tolerances, ergonomics, and usability are refined before production begins.

2. Material Selection and Testing:

Choosing the right material determines everything, from strength to weight. Common materials in Sports Equipment include carbon fiber, fiberglass, aluminum alloys, ABS plastics, and polyurethane foams.

Haumann Group assists brands in selecting and sourcing optimal materials. Our previous research with carbon-composite and plastic injection molding, for instance, provides us with the ability to produce super-light but super-strong parts suitable for high-performance sporting goods.

3. Tooling and Molds:

After the design is validated, the cuts and molds with high precision are made. Our capability of injection mold manufacturing ensures that every part of the product has the same geometry and texture quality as specified. For large-scale sporting goods equipment manufacturers, this stage is critical; consistency and dimensional accuracy determine the difference between a good product and an elite one.

4. Manufacturing and Assembly:

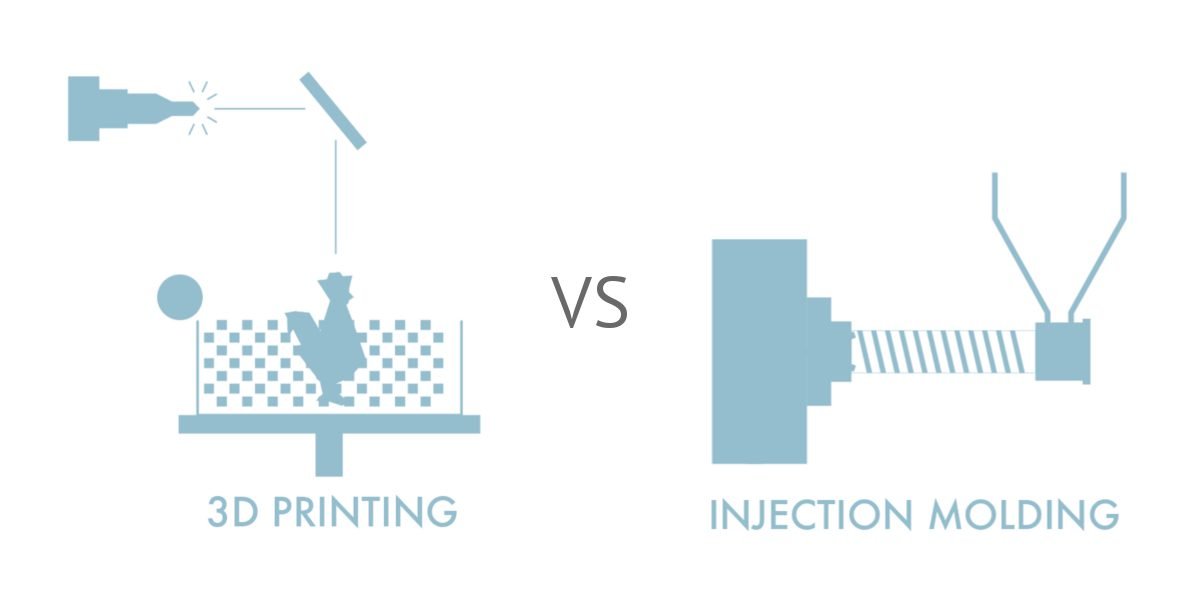

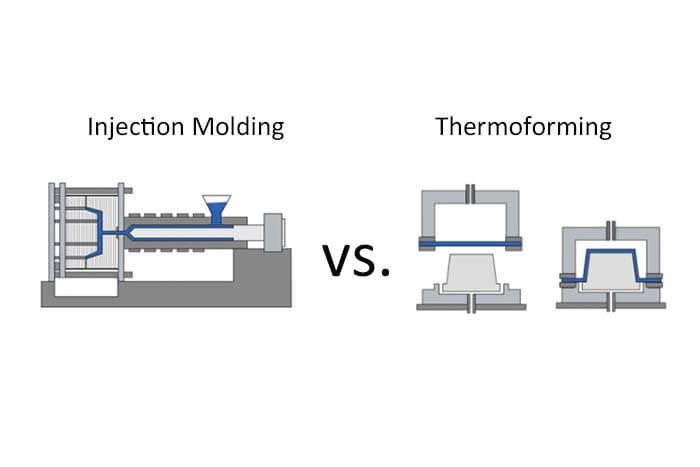

Production may include plastic injection molding, metal forming, CNC machining, or composite layup, depending on the product. For example, a snowboarding boot does need a combination of molded shells, stitched fabrics, and precision fasteners

We use automatic operations and proper assembling techniques to make sure that every product meets specific requirements. Our advanced product assembly services and component integration expertise allow brands to scale seamlessly.

5. Quality Testing and Finishing:

Every part is inspected for structural integrity, finish, and performance. Impact tests, flex tests, and visual inspections are all done before the packaging process. For quality control, whether it is for sports equipment manufacturers USA or adventure sports equipment manufacturers China, it is still the same controlling standard all over the world.

Global Trends in the Production of Sports Equipment

The sports manufacturing industry has now turned out to be worldwide. While the Chinese manufacturers of sports equipment take over the market production because of their scale and cost efficiency, many premium brands still prefer working with partners based in the USA for closer quality control and quicker communication.

That is why Haumann Group combines the advantages of both worlds, utilizing the global sourcing efficiency while being under American engineering supervision. Our hybrid production model provides speed, cost control, and consistent quality.

In 2025 and after, sustainability and customization will be the trends that are going to define the industry. The use of eco-friendly materials, recycled plastics, and the implementation of energy-efficient production processes are becoming indispensable for the top sports equipment manufacturers.

How to Choose the Right Sports Equipment Manufacturer:

The company you partner with for your sports gear is a very important decision. Here are some criteria to consider:

- Experience: A history of working with technical products.

- Material knowledge: Right knowledge of polymers, metals, and composites.

- Tooling precision: Proper capability to create molds and tooling in-house for precision

- Scalability: The capacity to handle the production of small prototypes or full-scale runs.

- Quality assurance: Compliance with ISO or equivalent standards for inspection and testing.

We bring together all these capabilities in a single location. From concept to packaging, our process guarantees that your product will reach the market sooner without sacrificing quality or brand image.

Haumann Group’s Role in Sports Equipment Manufacturing:

Haumann Group combines engineering precision with manufacturing agility. We have taken our processes from automotive and aerospace-grade molding to sports equipment product manufacturing with the same precision and reliability level that is always delivered.

The following are some of our services:

- Prototyping & development: transforming raw design concepts into actual production parts.

- Injection molding & composite fabrication: materials and processes that are ideal for lightweight and durable sports goods.

- Product assembly and testing: this guarantees that each part works as it should.

- Packaging & distribution: smooth movement from factory to customer.

We also have eco-friendly alternatives that benefit brands and help them keep up with the high-performance standards by reducing their carbon footprint.

Reasons To Opt For Haumann Group Over Other Manufacturers

We are not just another sporting goods equipment manufacturer offering just manufacturing like many others. We are the ones who build partnerships. Our U.S.-based operations are focused on precision and accountability, while our international network assists in managing affordable production suitable for global distribution.

The following are the reasons brands opt for us:

- Engineering competence: Supported by years of experience in tooling and injection molding.

- Flexibility: Ranging from small-batch testing to high-volume runs.

- Customization: Finishing, coloring, materials, and branding options that are tailored.

- Speed: Faster entry into the market thanks to optimized production workflow.

- Support: Open communication and technical assistance are provided.

We are the makers of the products that perform. Regardless if you are a novice trying to develop your first athlete’s accessory or one of the largest sports equipment manufacturers, we are there to help you.

The Trend Of Sports Equipment Manufacturing :

Modern athletes expect gear that’s lighter, smarter, and more sustainable. Manufacturers are now integrating sensor technology, recyclable materials, and modular components into design standard practice.

Haumann Group is continuously innovating in this area, using insights from automotive and aerospace plastics to develop durable and sustainable solutions for the sports industry.

We are not just keeping up, we are helping redefine what is possible in Sports Equipment manufacturing.

Frequently Asked Questions (FAQ)

Q1. Which materials are generally used in making sports equipment?

The commonly used materials consist of carbon fiber, ABS plastics, aluminum, and composites. The selection is made according to the specific requirements of the product in terms of strength, weight, and flexibility.

Q2. Is it the case that all sports equipment manufacturers are similar?

Not in any way. The top sports equipment manufacturers not only provide production but also design support, quality testing, and advanced tooling, among others.

Q3. What are the reasons behind the choice of the USA as the location for manufacturers by many brands?

The collaboration with sports equipment manufacturers in the USA provides the communication factor that is very good, the logistics are fast, and high-quality assurance is also high compared to the overseas-only options.

Q4. How can Haumann Group help with custom sports equipment?

We can provide end-to-end solutions, from design and prototype development services to tooling, molding, and final assembly.

Q5. How do you maintain quality during mass production?

By using precision molds, automated systems, and multi-point inspections at every stage of production, we ensure consistency across all pieces of Sports Equipment.

Conclusion: Building a Strong Future in Sports Manufacturing:

The first step to building a partner reliability, high-performance Sports Equipment is choosing right. Time goes from design and tooling to testing and final delivery; every detail matters for the product’s success.

At Haumann Group, we combine engineering excellence, innovation, and reliability to create sports gear that meets global standards. Whether it’s custom sports equipment product manufacturing, advanced molding, or eco-conscious production, our goal is simple: help brands deliver performance, durability, and trust.