Tooling Engineering & Mold Fabrication for Injection Molding

Tooling Engineering & Precision Mold Fabrication | Rapid Tooling & DFM Analysis | US–China Scalable Production Support

Tooling Engineering & Mold Fabrication Capabilities

In Tooling Engineering & Mold Fabrication for Injection Molding, we specialize in delivering precise, high-quality tooling solutions that are optimized for mass production. Our advanced mold fabrication and engineering processes ensure that every project meets rigorous performance and dimensional requirements. Our German-engineered tooling systems ensure dimensional accuracy, repeatability, and long-term production stability across demanding applications, including automotive, footwear, industrial, and consumer products.

With engineering leadership in Houston and scalable mold manufacturing in Foshan, we help OEM partners transition efficiently from prototype validation to high-volume production. Our integrated approach combines DFM analysis, rapid tooling development, and production-ready mold fabrication to reduce risk, improve cycle efficiency, and ensure consistent manufacturing performance.

End-to-End OEM Manufacturing:

- Precision injection mold engineering

- Rapid tooling for production validation

- Multi-cavity molds for high-volume output

- Tight tolerance mold fabrication

- Production-grade tooling materials

- US engineering + China fabrication scale

Design for Manufacturing (DFM) Engineering Support

Our DFM engineering process ensures your tooling is optimized for performance, cost efficiency, and production scalability before fabrication begins.

Key DFM advantages:

- Early detection of tooling and molding risks

- Optimized part geometry for injection molding

- Reduced production cost and cycle times

- Improved dimensional stability and repeatability

- Faster transition from prototype to mass production

Tooling Engineering & Mold Fabrication Expertise for Reliable Production

HAUMANN provides rapid tooling solutions using production-grade materials, allowing OEM partners to validate designs under real manufacturing conditions.

Capabilities include:

- Aluminum and steel rapid mold fabrication

- Prototype tooling for pilot production

- Functional testing with production materials

- Bridge tooling before full production molds

- Faster product launch timelines

Tooling Engineering & Mold Fabrication for Scalable Injection Molding Production

Explore how our tooling engineering and mold fabrication services support your product development from prototype validation to high-volume injection molding production. With advanced mold design, CNC precision machining, and global tooling manufacturing capabilities in Houston, USA, and Foshan, China, we deliver reliable, production-ready molds engineered for long-term performance and scalability.

Our integrated tooling platform combines German-engineered mold design, rapid tooling development, and production-grade mold fabrication to ensure dimensional accuracy, repeatability, and process stability. HAUMANN helps OEM partners reduce tooling risks, optimize cycle efficiency, and accelerate the transition from engineering development to full-scale manufacturing.

The Haumann Advantage:

- Precision Mold Engineering: Injection mold tooling designed for dimensional accuracy, repeatable performance, and stable high-volume production.

- German-Engineered Tooling Systems: Advanced mold design and process control ensure tight tolerances, tooling durability, and consistent part quality.

- Rapid Tooling & Scalable Fabrication: Fast tooling development with multi-cavity mold capability to support production validation and mass manufacturing scale.

- Full-Service Tooling Support: Integrated tooling engineering, fabrication, validation, and lifecycle support for reliable OEM manufacturing programs.

End-to-End Tooling & Mold Fabrication Capabilities

Injection Mold Tooling Built for Production Stability

✅ Engineering-led mold design & risk mitigation

✅ High-precision cavity & core machining

✅ Cycle-time optimization & cooling efficiency

✅ Structured mold trials & validation process

✅ USA-based engineering with scalable production support

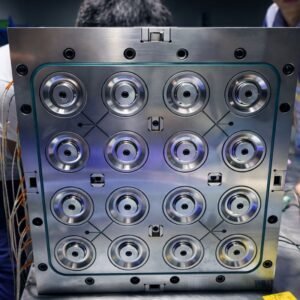

Multi-Cavity Mold Tool:

✔️High-precision mold tool

✔️Built for mass production

✔️Consistent part quality

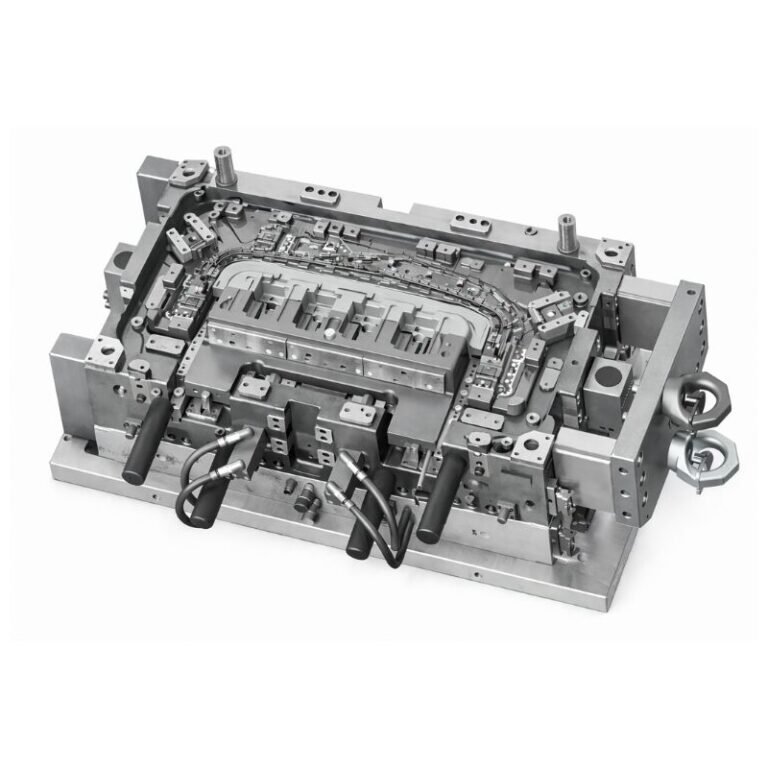

Injection Mold Assembly:

✔️Precision mold assembly

✔️Tight tolerance control

✔️Reliable production output

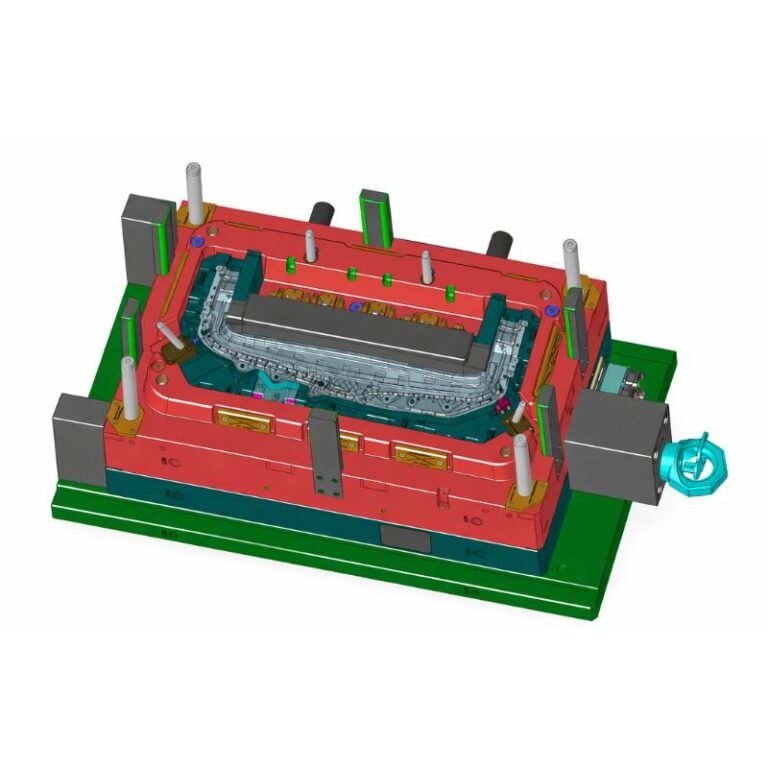

Mold Engineering Design:

✔️Optimized mold design

✔️Improves molding efficiency

✔️Accurate part production

Prototype Mold Tool:

✔️Rapid prototype tooling

✔️Supports pilot production

✔️Faster product validation

Mold Fabrication & Build Control

Our tooling engineering and mold fabrication process is built around precision, durability, and production readiness. HAUMANN’s German-engineered tooling systems ensure injection molds deliver consistent part quality, tight tolerances, and long service life for high-volume manufacturing programs.

Fabrication scope includes:

- Tool steel selection based on material, volume, and lifecycle requirements

- CNC machining, EDM processing, and precision mold cavity creation

- Mold assembly, fitting, alignment, and functional verification

- Cooling channel optimization for stable cycle times

- Full tool qualification and readiness validation before production launch

Validation & First Shot Support

We provide complete tool validation and first-shot support to ensure molds are production-ready and optimized for stable, repeatable injection molding performance. Our engineering team verifies tooling function, dimensional accuracy, and process stability before full production release.

Validation activities include:

- First shot trials and process parameter optimization

- Dimensional inspection and tolerance verification

- Cycle time, cooling, and molding performance evaluation

- Tool adjustments and engineering refinements prior to mass production

Integration with Production

HAUMANN’s tooling engineering team works directly with our injection molding operations in Houston and Foshan, ensuring seamless transition from mold fabrication to high-volume production. This integrated approach improves efficiency, quality, and production scalability.

Integrated advantages:

- Faster feedback between tooling engineering and production teams

- Reduced development time and fewer tooling revisions

- Improved molding stability, repeatability, and output consistency

- Single-source accountability from tooling through mass production

How It Works

Our structured tooling engineering process ensures predictable development, reduced risk, and faster time-to-production.

- DFM review and engineering alignment

- Tool design and precision mold fabrication

- Internal validation and first-shot trials

- Production release and manufacturing scale-up

Why OEM Partners Choose Haumann for Tooling

HAUMANN is a trusted partner for precision injection mold fabrication and tooling engineering, supporting OEMs across automotive, industrial, consumer, and footwear industries.

- Engineering-led DFM and tooling development

- Proven expertise in complex injection mold fabrication

- Seamless integration between tooling and production

- Dual-base manufacturing support in USA and China

Reduce Tooling Risk Before Cutting Steel

Begin your program with a professional DFM review and tooling engineering consultation to minimize development risk, manage costs, and expedite production readiness.

Our engineering team evaluates part design, material selection, mold flow, and tooling strategy to ensure your injection molds deliver reliable performance from first shot through full production.