When people talk about plastic manufacturing, they often refer to injection molders, the teams and facilities responsible for transforming raw plastic pellets into precise, high-quality parts used in consumer goods, electronics, automotive components, medical devices, packaging, and countless other industries. But for many product developers, OEMs, and engineers, the question still remains:

What do plastic injection molders actually do?

Whether you are researching the U.S.-based production, checking suppliers, or setting up a new plastic product, it is very important to know how injection molders operate and how to pick the right one, too.

Haumann Group in Houston, Texas, among others, provides complete and total plastic injection molding, beginning-to-end solutions for startups, small businesses, and large manufacturers who want to produce very reliably, flexibly, and cheaply.

Below is a detailed explanation about the role injection molders play and what you need to think of before hiring a skilled manufacturing partner.

What is a Plastic Injection Molder?

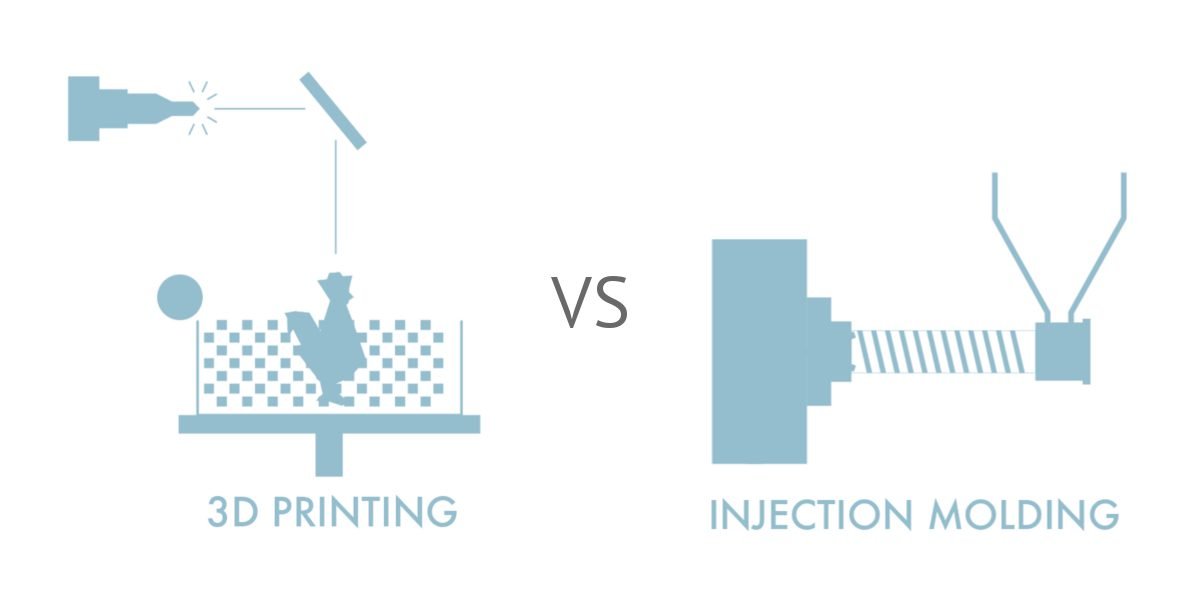

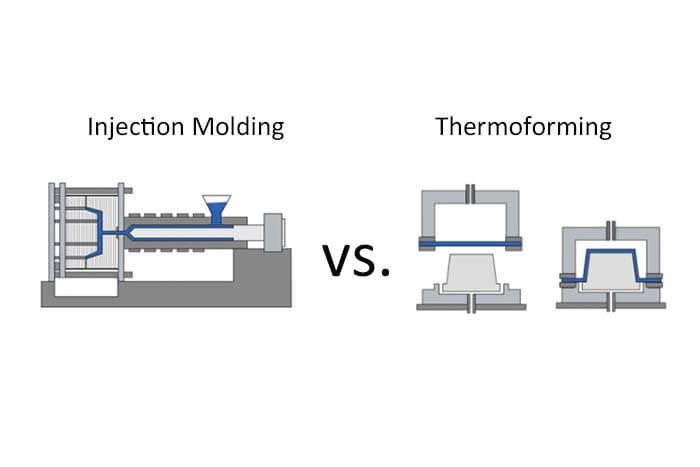

A plastic injection molder is a manufacturer whose expertise lies in the production of components through the injection molding process, a technique in which molten plastic is melted into a steel or aluminum mold under high pressure, cooled, and then ejected as a finished part.

Expert molding companies take care of everything, such as:

- Product engineering & DFM

- Prototyping

- Tooling design & mold construction

- Material selection

- Low, medium, and high-volume production

- Secondary operations

- Quality inspection & compliance

- Packaging and logistics

Credible molders put their main emphasis on uniformity, narrow tolerances, and repeatability; these are the very factors that most industries will not compromise on their precision.

Core Services Provided by Professional Injection Molders:

Below are the primary services that your injection molding partner should be able to offer if they are professional.

1. Product Engineering & Design for Manufacturing (DFM):

Before a mold is created or any material is injected, your design must be optimized for manufacturability. A professional molder will provide you with the following assistance:

- Wall thickness analysis

- Draft angle corrections

- Gates and flows optimization

- Structural reinforcements recommendations

- Material performance reviews

- Cost reduction strategies

The services mentioned above will ensure that the molding process of your component is done evenly and without any defects like distortion, sink marks, or high production costs.

2. Mold Making & Tooling Services:

The injection molding process involves a precision mold that is either made of steel or aluminum, depending on the required production lifespan.

Molders provide the following services:

- Mold design

- CNC machining

- Electrical discharge machining (EDM)

- Mold trials

- Validation of molds

- Maintenance and repair

Companies that need long-term, high-volume production prefer the more durable steel molds, whereas startups may opt for aluminum tooling, which is less expensive, for faster market entry.

3. Full Plastic Injection Molding Production:

This is the main activity that molders perform daily.

In the workflow, an injection molder uses highly specialized equipment, like:

- Hydraulic injection molding machines

- Electric injection molding machines

- Systems for removing parts by robots

- Quality control inspection equipment that is fully automated

During the whole process, molders keep track of:

- Temperature

- Injection pressure

- Cooling time

- Cycle speed

- Material flow

It’s their responsibility to make sure every part is identical to the customer’s specifications, regardless of whether you ask for 500 units or 5 million.

Haumann Group is a supplier to the brands in the regions of Houston and The Woodlands, and also to those located anywhere in the United States, with its injection molding services covering low, medium and high volume production.

4. Material selection & resin guidance:

Plastic resin selection constitutes a very important factor. A reliable molder will assist in the selection of materials based on:

- Strength

- Flexibility

- Resistance to chemicals

- Tolerance to heat

- Compliance with FDA, UL, or ISO standards

- Anticipated product life

The following are some of the most widely used resins:

- ABS (Acrylonitrile Butadiene Styrene)

- PP (Polypropylene)

- PE (Polyethylene)

- PC (Polycarbonate)

- Nylon

- TPU (Thermoplastic Polyurethane)

This consultation helps avoid failure, defects, or unnecessary costs.

5. Secondary operations:

The project you are working on may require more than just molding parts. Molders usually offer the following secondary operations:

- Ultrasonic welding

- Thread tapping

- Overmolding and insert molding

- Heat staking

- Painting or coating

- Kitting & assembly

- Labeling & packaging

This is especially beneficial for the U.S. manufacturers who want a single-source supplier instead of juggling multiple vendors.

6. Quality Control and Compliance:

High-quality molders follow strict quality control procedures, including:

- First article inspection (FAI)

- Dimensional measurement

- Material verification

- Surface finish inspection

- Final batch testing

The industries such as medical, automotive, and aerospace need documentation and traceability, and a great molder will do both.

How Manufacturers Choose the Right Injection Molding Partner:

Choosing your molder is one of the most important decisions in your supply chain. Here’s what U.S. companies mostly look for:

1. Location & Responsiveness:

Most manufacturers need domestic suppliers for faster lead times and easier communication.

Haumann Group is strategically located in Houston, serving:

- Houston

- The Woodlands

Local production reduces shipping costs, improves oversight, and keeps supply chains stronger.

2. Capabilities & Equipment:

Verify that your molder offers:

- The right tonnage machine range

- Automated systems for consistency

- In-house tooling capability

- Ability to scale from low to high volume

Haumann Group provides complete plastic injection molding solutions under one roof.

3. Experience With Similar Parts:

If your product is:

- A clip

- A cover

- A connector

- A bracket

- A housing

- A sensor mount

- A consumer product component

You should choose a partner who has manufactured similar products; they will produce better tooling and offer smarter engineering support.

4. Material Expertise:

Your molder should help you choose the optimal resin and identify alternatives that reduce cost or improve performance.

5. Transparent Pricing & Lead Times:

Red flags include:

- Unclear quotes

- No breakdown of tooling vs production

- Unrealistic timelines

A trusted molder provides complete clarity.

6. Strong Communication & Engineering Support:

The best injection molders don’t just “run machines”; they collaborate with you from concept to mass production.

Why Houston Companies Choose Haumann Group:

- U.S.-based engineering & molding facility

- Fast turnaround times

- ISO-level quality

- Low, medium, and high-volume production

- Competitive pricing

- Reliable communication

- End-to-end services (tooling + molding + assembly)

Whether you’re producing a consumer product, industrial component, or custom-engineered part, our team delivers consistent quality and scalable production.

FAQs About Plastic Injection Molders:

1. What does an injection molder actually do?

They design molds, select materials, operate injection molding machines, inspect quality, and deliver finished plastic components.

2. Are injection molders expensive?

Tooling is the major cost. Once the mold is built, per-part pricing becomes extremely low, especially for medium and high-volume production.

3. Can injection molders handle low volume?

Yes, Haumann Group provides low-volume injection molding for startups and early prototypes.

4. How long does it take to make a mold?

Typically 3–8 weeks depending on complexity, materials, and part geometry.

5. Why choose a Houston-based injection molder?

Domestic partners offer faster communication, shorter lead times, lower shipping costs, and more reliable supply chains.

Conclusion: Get a Quote From Haumann Group (Houston, Texas):

Whether you need engineering support, tooling, or full-scale production, Haumann Group is ready to help.

Serving Houston, The Woodlands, and nationwide U.S. brands

- Contact us today

- Request a quote